Versatile Foundry Production Solutions From Precision Aluminum Sand Casting & Machining Services To Expert Engineering & Core-making Capabilities

Denison Industries delivers a range of quality foundry services specializing in custom, complex machined aluminum sand castings. Our AS 9100 D & ISO 9001:2015 certified facility is streamlined to deliver cost-effective aluminum manufacturing solutions with precision results from prototype to production.

Innovative Engineering Solutions

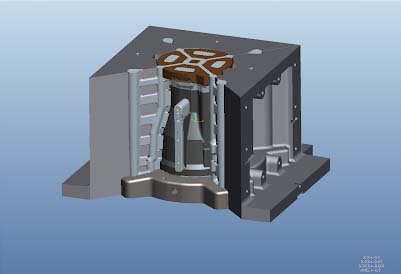

Denison Industries employs casting engineers who deliver optimized manufacturing solutions for your unique application. For example, our engineering department utilizes advanced magma simulation software to design the fit and function in order to accommodate the end user’s casting requirements.

Our Foundry Is Streamlined To Deliver Superior Aluminum Castings

Our state-of-the-art foundry and pattern shop is engineered to delivery efficiency.

Our production process incorporates an advanced pull system utilizing PC-generated Gantt charts for scheduling material through the facility. We also offer bar-coding utilization for shipping as per your product requirements.

Through continuous development of our foundry technology, our human resources and our advanced product management systems, Denison Industries is propelling ourselves into the future of precision American manufacturing.

With every custom project our foundry takes on, we are molding a brighter future for our community and country. At Denison Industries, we blend the industry’s most cutting-edge technology with the time-honored art of metalcasting to produce the finest quality aluminum castings available on the market.