Awards and Achievements Earned Through Innovative Manufacturing Solutions

Since 1971, and through multiple generations, we at Denison Industries have dedicated ourselves to earning business by manufacturing at a consistently high level and establishing long-term business relationships. Our current customers value both of these attributes.

Here are just a few of the most recent commendations we have received from our customers:

Denison’s performance has been instrumental in achieving the success of our cast vehicle hull program.

The quality of your castings… [is] unmatched in the industry.

The team at Denison has shown the expertise and attention to detail that is to be commended.

Award-Winning Machined Aluminum Castings and Quality Foundry Services

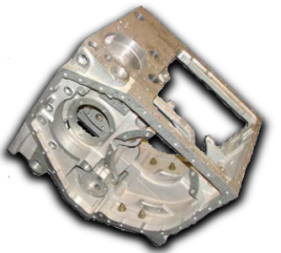

American Foundry Society Casting Competition Casting of the Year

By converting this previously machined-and-welded design into a casting, lead time and labor were drastically reduced. Overall, the casting conversion resulted in a 50% reduction in lead time and a 15-20% reduction in cost.

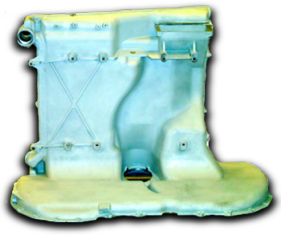

American Foundry Society Casting Competition Best-in-Class

This casting facilitated close adherence to cost and weight requirements for the component. Due to the size of the casting in comparison to the wall thickness, Denison maintained tight process controls to ensure directional solidification for accurate, mechanical properties.

American Foundry Society Casting Competition Best-in-Class

Denison Industries converted this component into a casting from a labor-intensive, high-cost fabrication. The original process consisted of machining and welding over ninety (90) individual components and was improved by a casting process requiring only three cast assemblies.

American Foundry Society Casting Competition Best-in-Class

Machined and assembled components would have required an estimated 15-20 separate parts. This assembly would have cost an estimated 75% more than the complex, 27-core casting. Lead time on the casting was reduced by 50% over the multi-piece assembly.

American Foundry Society Casting Competition Best-in-Class

This casting conversion eliminated external tubing, hydraulic lines and passages by casting them into the design. This design required 77 cores to achieve the intricate internal passageways. Denison’s design team worked with the patternmaker and customer to ensure the core package was assembled in the proper order.

U.S. Navy Award of Excellence

Denison Industries is honored to provide our U.S. military forces with top quality, complex castings to assist them in protecting the U.S.A.– and we’re proud to have been awarded the U.S. Navy “Award of Excellence” for our work.